Our Technology

Electrospinning is

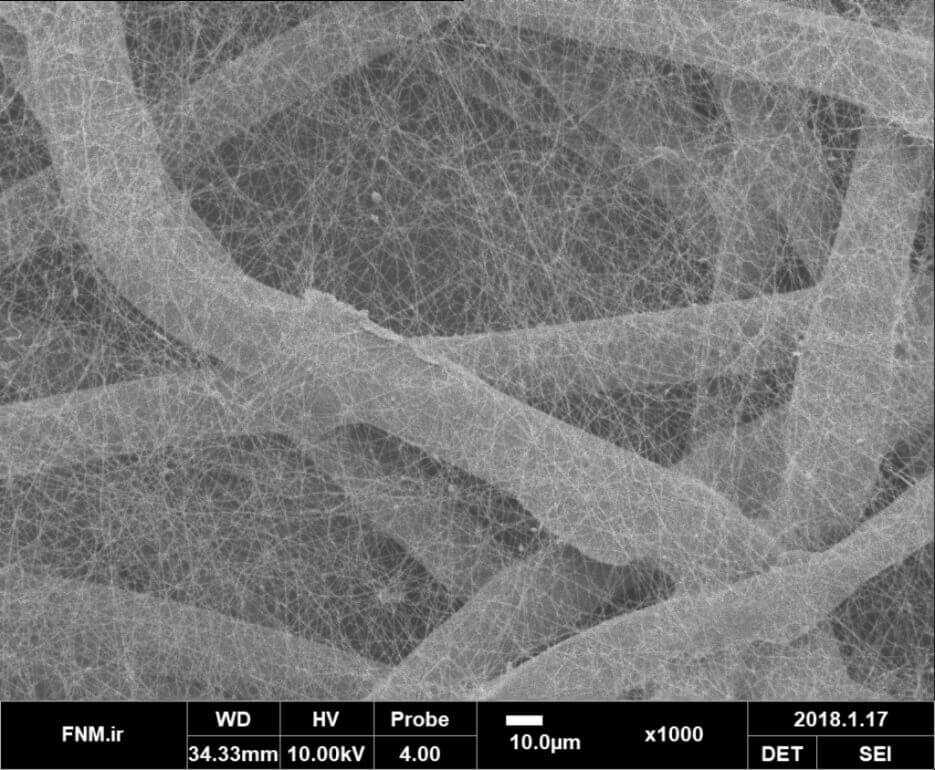

Electrospinning is a fiber production method that employs electric force to draw

charged jets of polymer solutions or polymer melts. The diameters of these jets

are generally in the order of some hundred nanometers. When an external electrostatic

field is applied to a conductive fluid, for example a spinning solution, a suspended

conical droplet, which is called Taylor cone, is formed.

Electrospinning occurs

when the electrostatic field is strong enough to overcome the surface tension of

the liquid. The liquid droplet then becomes unstable and a tiny jet is ejected from

the surface of the droplet. The ejected jet is deposited on a collector as a result

of the electrostatic field that is provided by a power supply between the spinneret

and the collector and is applied to spinning droplets. As the tiny jet reaches the

collector, an interconnected web of fine sub-micron size fibers are collected on

the collector.

Electrospinning provides

a relatively versatile method of creating a variety of ultrathin fibers (nanofibers).

Nanofibers with some specific properties can be prepared if appropriate solution

or processing parameters are performed. However, electrospinning generally has relatively

low productivity compared to other spinning processes, because the polymer solution

has to be fed at comparatively slow rates and only electrostatic forces are used

to obtain the ultrathin fibers. In order to overcome the aforementioned drawback,

we employed blown electrospinning technique for increasing throughput up to 3 times

compared to conventional electrospinning systems. The combination of the air blowing

force and the electrostatic force is capable of overcoming the high surface tension

of the polymer solution, therefore, the rate of converting solutions to nanofibers

increase significantly. Additionally, the solvent evaporation is accelerated by

blowing air which is a necessary condition for the fiber formation before the jet

reaches the collector during the process. Therefore, many useful polymers, which

previously could not be electrospun, now are processed easily by using the blown

electrospinning process.

FNM’s blown electrospinning machines, which its technique was patented and uses

electric and air blowing forces to produce various nanofibers, can be supplied in

lab, pilot and industrial scales.