The effect of nanofiber in performance and efficiency of the respiratory mask

The particles in the air have different sizes. Despite their chemical characteristics, the damage they have is due to their tiny diameters. With the growth in technology, especially nanotechnology, and the industrialization of most cities in the country, the increase in air pollution and contagious diseases is a major rising problem. Using common air filters in the market to protect against the pass of particulate matter into the machines such as automobile, gas turbines, personal protective equipment such as respiratory masks do not have a significant effect. As a result, better filtration efficiency is needed. Nanofiber respiratory masks are one of a kind.

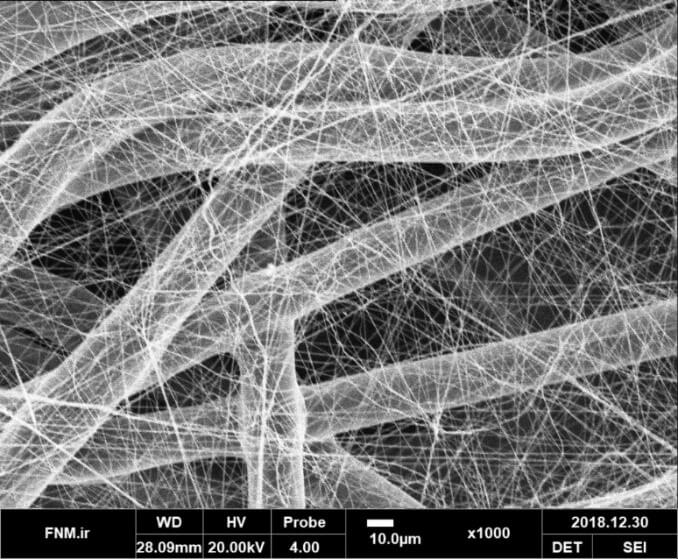

In recent years, nanofiber filter media is widely being used in various industries. Therefore, using nanofiber filters with high filtration efficiency, low-pressure drop, and being economical is becoming very common. Usually, in these types of masks, one or a couple of nanofiber layers will be coated on a non-woven substrate with pores.

The role of nanofiber media in respiratory masks

Nanofiber media plays a crucial role in the efficiency and performance of all types of respiratory masks. Therefore, they are usually coated on the non-woven media for trapping particles.

Nanofiber characteristics in respiratory masks

The high aspect ratio, high porosity, and very tiny pores of a nanofiber can lead to better efficiency of particulate matters in respiratory masks. Small pore size and high aspect ratio prevent the passing of 0.3-micron particles. As a result, the efficiency of nanofiber masks increases. Also, due to the high porosity in nanofibers, the air molecules can pass easily. That is the main reason for the low-pressure drop in nanofiber masks, which leads to better breathability of maskss.

The features of using nanofiber respiratory masks:

1- Significant increase in filtration efficiency

2- Low-pressure drop (better breathability)

3- Long life span